SERVICES

IPACK specialize in supply chain management. We can satisfy efficiently to our customer in automotive industry and we are customize our services follow the customer requirements.

SUPPLY CHAIN SOLUTION

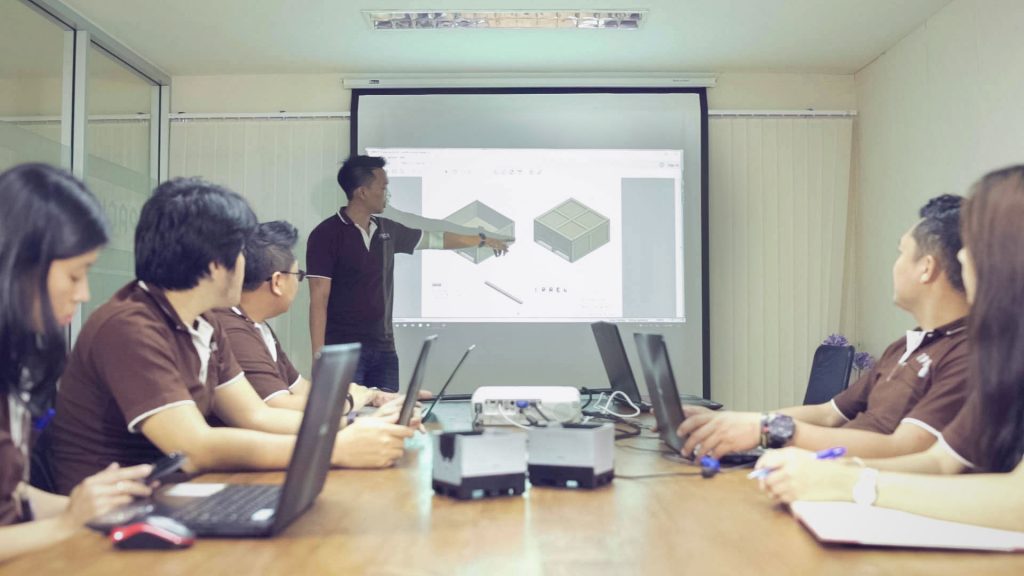

We have improvment team that understands the operator functions, we can design operation and system to help make your work more efficiently.

IPACK ADVANTAGES :

1. Reduce Over Production Waste

2. Reduce Over Processing Waste

3. Reduce Transportation Waste

4. Reduce Waiting Waste

5. Reduce Inventory Waste

6. Reduce Defects Waste

7. Reduce Motion Waste

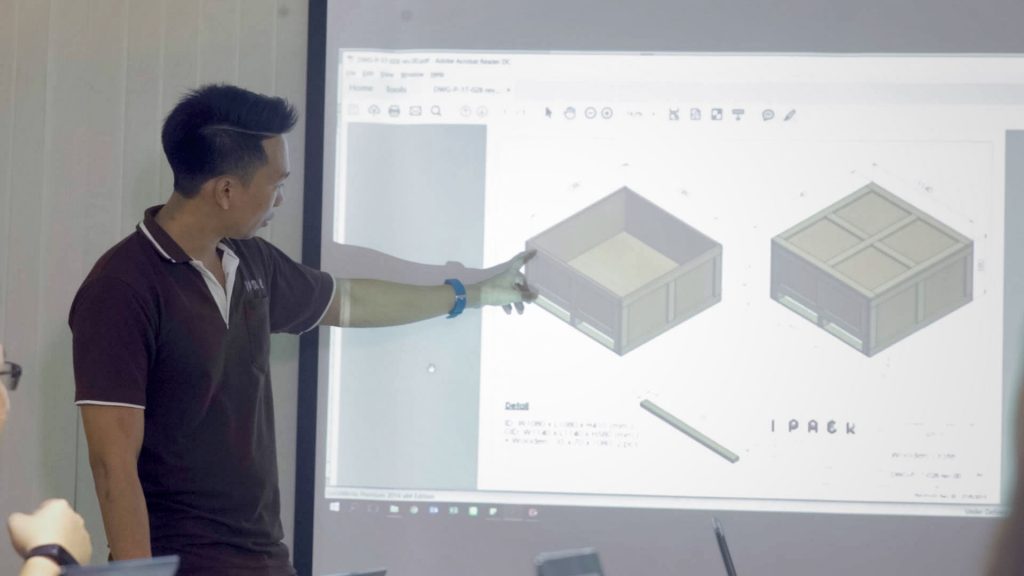

PACKING

We specialize in the packing of automotive parts as well as packaging design for the benefit of shipping as well. IPACK Customer’s Parts of material are dispatched globally more than 100,000 items per year including Europe, Asia, and South America without packaging claim from Customer. (Zero Claim)

Packing Service including Design Packing, Loading Parts, Receiving Parts, Quality Checking, Packing follow standard, Tracking Inventory of Parts or Finished Goods, Transportation to Customers and Reporting.

Packing Services

1: Loading 2: Receive 3: Checking 4: Packing 5: Storage 6: Delivery 7: Report

PACKAGING MANAGEMENT

The biggest problem with the packaging in the automotive industry, packaging is lost and does not know the status or location of your package in real time. So, customers can not plan to use the packaging in accordance with the production plan. Therefore, our packaging management services to solve customer pain.

If required information will processed to i-Wis system, which will be calculated and dispatched to staff for preparing the packaging. These will be processed to Loading / Receiving / Cleaning / Storage / Preparing and delivery procedure which can be followed up, recorded, analyzed and reported to database. Customers can track containing status that can help them to forecast production plan with efficiently and consistency. This is to avoid insufficiently of packaging requirement.

Packaging Management Services including Design Packaging, Loading Packaging, Cleaning Packaging, Receiving Empty Packaging, Storage, Preparing, Tracking, Delivery and Reporting

Packaging Management Services

1: Loading 2: Receive 3: Cleaning 4: Storage 5: Prepare 6: Delivery 7: Report

Packaging Material Supply

Packaging Material Supply including Design Packaging, Test Packaging as standard,

Production Packaging, Packaging Stock Management and Just In Time delivery.

Carton Box

1. Single wall 2. Double wall 3. Triple Wall 4. Diecut box 5. Partition set

Wooden Pallet / Wooden Box

1. Heat treat at core temperature

2. Methyl bromide fumigation

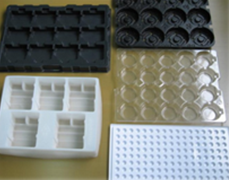

PP Tray / Vacuum Process

PP Tray

Vacuum Process

Vacuum Process

Foam

Foam sheet

Foam packaging

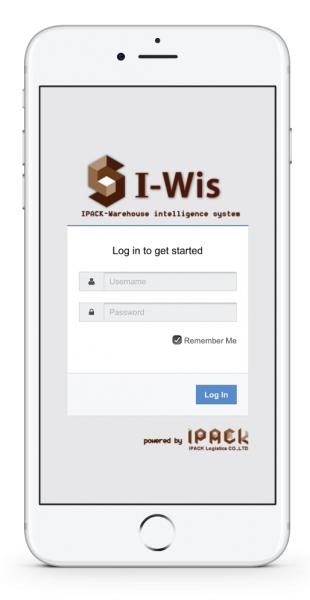

I-Wis

I-WIS

I-Wis Advantages:

- Online tracking system on webapplication

- Clients can track containing status that can help

to forecast production plan with efficiently and consistency. - Real time tracking and accurate data

- Quickly generate report

- Can retrieve backward data

- To avoid insufficiently of packaging requirements

- Record all processes and quality data

- Easy to manage logistics functions

- Flexible system with customer